Learning from Failure

(illustration: Leonhard Rothmoser).

In 2011, Ineke Hans launched the 380, an injection-moulded plastic chair for Dutch brand Ahrend. Faced with manufacturing issues, however, the chair quickly fell from production. Then, in 2021, the design returned under a new name: Rex.

I started working on Rex back in 2007, when I was approached by Ahrend, a historic Dutch design company. Ahrend had worked with some great designers like Friso Kramer and Wim Rietveld, so it seemed like a real opportunity.

The company asked me to create a chair concept that they could show in Milan during the Salone. I think they thought I might do something crazy to draw attention to their exhibition, but I wanted to make a sensible chair and show the world that I could work within heavy industrial design, because not many women get the chance to do that.

So I looked into Ahrend’s factories and archives to see what could be a good fit, before presenting three different proposals. Funnily enough, they selected the only design they didn’t have the capacity to produce themselves – it had to be made in China. It was a serious project, but then the 2008 financial crisis hit. Spending started to be cut and, by the time they were ready to produce my chair, I discovered that they had only invested in rough moulds to create prototypes. Even so, when the chair launched in 2011, people liked it. It won a few awards and it was asked for in a lot of projects – but Ahrend couldn’t deliver. So much had been cut from the industrial process that, once the chairs arrived from China, they had to go on to a company in the Netherlands to be finished. It became very expensive.

“It was, personally, a disaster and I was always looking to see if there was another way to get the chair made.”

It was, personally, a disaster and I was always looking to see if there was another way to get the chair made. I still owned the rights and companies would sometimes ask if they could take it on. But the new moulds would have cost around €250,000. Finding a new producer doesn’t happen automatically.

Then, about four years ago, I got in touch with Circuform, a small company that aims to give industrially designed furniture a circular life. I had always intended Rex to be made from recycled plastic, but I’d never been able to verify if that initial version was, and there were aspects of the engineering that I had never been satisfied with. But Circuform invested in the idea to make sure it happened, as well as working with me to correct the engineering. They created new moulds and I also insisted on a campaign to properly explain the idea behind the piece and its circularity.

“Over the last decade my fantasy of working with big companies has completely changed”

The new chair launched in 2021 and has been nominated for the Dutch Design Awards – it’s been a long journey but a real learning experience. It was such a disappointment to work with a historic manufacturer, of whom you have certain expectations, and have the project end badly. It turned out to be much better to work with a smaller company who could back Rex properly.

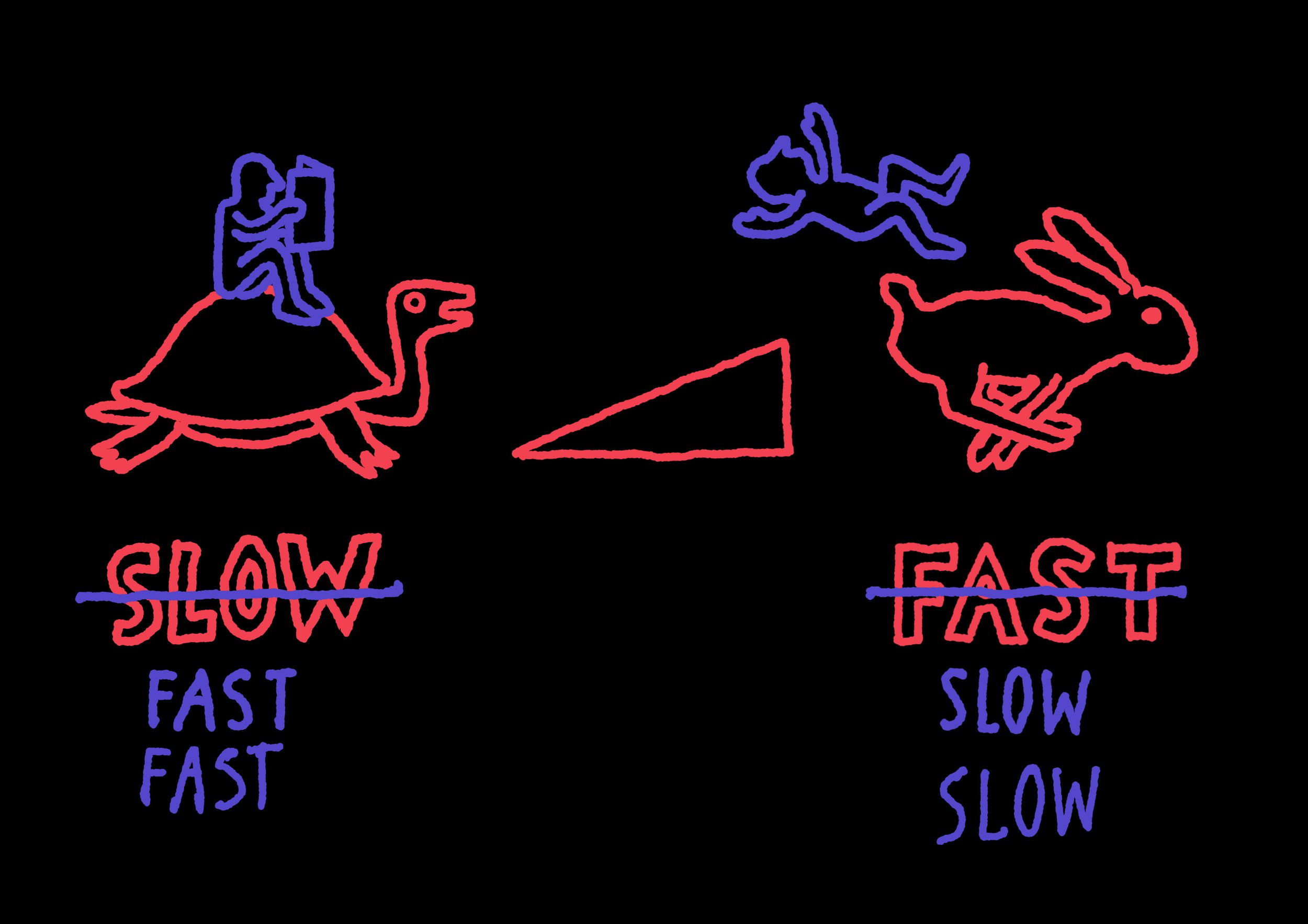

In fact, over the last decade my fantasy of working with big companies has completely changed. I’m very happy with what Rex became and I’m happy that I took things slower. That’s how I now want to work: focus on adventures and projects that interest me, rather than worry about working for big names.

Words Ineke Hans as told to Oli Stratford

Illustration Leonhard Rothmoser

This article was originally published in Disegno #34. To buy the issue, or subscribe to the journal, please visit the online shop.