Aggregate: A Composite Account

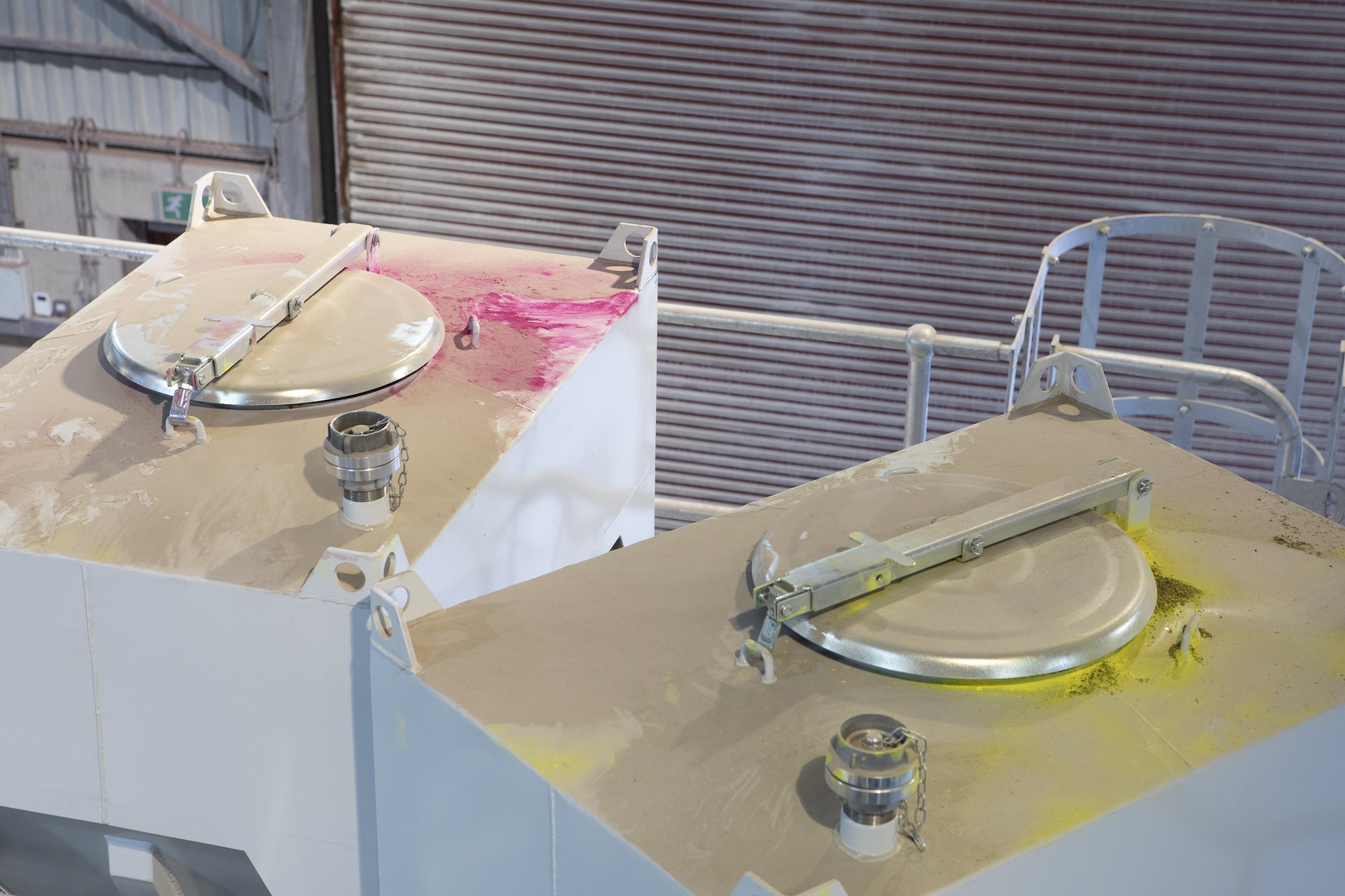

The images accompanying this text were taken by photographer Donald Milne and document the Kenoteq production facility on farmland to the east of Edinburgh. They show the facility as it geared up for the launch of Kenoteq’s K-Briq on the UK market in spring 2023, revealing the process through which the company’s waste-based bricks are manufactured.

The following text details the production of bricks manufactured using construction waste. It has been written using fragments of quotes taken from original interviews with those involved in the practice. These quotes form the main body of the text, loosely bound together with short explanations and linking phrases.

So a brick is made from surrounds, of earth carved up and pressed into blocks, baked, which architect Andy Groarke describes as a building material having historically been really provisional, he says, of being a useful way of taking material from the local environment to make effortlessly vernacular architecture.

And yet this idea of vernacular bricks is essentially nostalgic, because we now we make 3tn bricks every year, says Groarke, although we should fact check that, he says, and the number online seems to be somewhere around 1.5tn bricks instead, of which 1.3tn are said to have been manufactured in Asia.

That leads Groarke to think about how bricks were once local things, he says, but now wonder how many of us as architects truly research the origins of the materials that we are specifying.

Groarke’s studio, Carmody Groarke, is based in the UK, a country that used 2.6bn bricks in 2019, of which 500m were imported due to a domestic shortfall, and this is a figure that corresponds with how bricks, globally, have undergone a transition from local craft object to industrial good, says James W.P. Campbell, whose 2003 Brick: A World History notes that the brick is a building material that has moved from being a simple clod of earth kneaded into a loaf-like mass by hand, it says, to the metric-sized precision-moulded factory- produced object made today.

This is a story of mass-production that belies the structural and material complexity of bricks, however, because although a brick is a simple thing, says Sam Chapman, an engineer who co-founded Scottish brick manufacturer Kenoteq Ltd in 2015, it’s a thousands-of-years-old technology – one whose name, sig, in the Sumerian language of Mesopotamia, says Campbell, from whence moulded bricks are said to have originated in around 5000 BCE, was used to mean both a building and a city, he says.

And Sumerian’s linguistic presentation of bricks as the core to architecture and urbanism is neat, because a brick can be thought of as ordered earth, says Ben Bosence, co-founder of British architecture practice Local Works Studio, insofar as a brick is the rawest material you can get, he says, because it’s basically a human rectangulation of raw material.

Traditionally, this material has been clay-rich brickearth, which is fired in kilns at between about 900 and 1,150°C, says Campbell, for at least 8 to 15 hours if the clay is to gain the resilience of stone that is typical of a fired clay brick, he says, so I guess the hidden story about brick is that it’s extremely carbon intensive to produce, says Bosence, because although once it’s made it’s wonderful and you can potentially reuse it forever, there’s this really heavy initial carbon hit which you’ve got to take if you make a traditional ceramic brick.

Which gives us twin environmental problems of contemporary bricks – they’re shipped from all around the world, says Bosence, and they are made by obscenely high-polluting technologies and industries, but we’re just picking them off the shelf from a builder’s merchant, he says.

Because where materials are from is not well known, he says.

Image: Donald Milne.

There are some immediate responses to this that may help improve the legibility of materials’ origins, such as manufacturers ensuring that bricks don’t travel very far, says Chapman, and also taking the raw materials that are in your area to reduce the carbon emissions of transport, adds Gabriela Medero, who is a civil engineer, a professor at Heriot-Watt University, and the other co-founder of Kenoteq, which would amount to a basic policy of keeping material movements to a minimum, they say.

But this approach would not touch the carbon costs of firing, with India alone producing 200bn bricks in 2011, almost all of which were fired in kilns that burned huge amounts of coal, reports the World Bank, and which emitted 76m tonnes of carbon dioxide, with this only being resolved if you reconsider the materials from which bricks are made, given that the energy for firing clay is all wrong, says Medero, who also rejects the alternative of cement bricks because 8 per cent of carbon emissions worldwide come from cement, she says.

So, no cement, no fire, she says.

This dual prohibition prompted Medero’s development of the K-Briq, a new design for a brick that enters mass production for the UK market in spring 2023, and which is made from more than 90 per cent waste materials taken from construction and demolition, using sand, using gypsum, using pieces of ceramics, says Medero, all materials we have used for hundreds of years, she says, and which we know are not going to change – they are what they are.

Kenoteq was founded by Medero and Chapman to deliver the K-Briq as a commercial product, which began life as a research project at Edinburgh’s Heriot-Watt several years earlier, and is now a brick with a material formula built up from old rubble, old stone, old concrete, old mortars, says Chapman, a lot of old brick, old gypsum from waste plasterboard that you don’t see from the outside, he says, but inside of which there’s all this history of construction waste.

Which is an exploration of waste streams that provides a broad material palette for architectural use, because construction and demolition accounts for more than a third of all waste generated in the EU, reports the European Commission, which hurts me when I see that demolition, says Medero, when I see historical buildings being pulled down without any consideration, she says.

There are various national and international guidelines in place that aim to limit the environmental impact of demolition, such as the EU’s 2008 Waste Framework Directive, which aimed for 70 per cent of all construction and demolition waste to be recycled by 2020 and that is now being reformulated, but if you ask the demolition industry what is happening to the waste materials, says Ward Massa, co-founder of Dutch architectural materials company StoneCycling, they’ll say they are already doing a fantastic job recycling the waste, but if you zoom in on what recycling means to them, he says, the materials are just broken down and used as filler for roadbeds or the foundations of new buildings.

Which is really downcycling, says Massa, and this in spite of the fact that construction and demolition waste is by far the biggest waste stream that we have in the Netherlands, he says, and I believe in the UK it’s about 65m tonnes each year, which is 4.7m truckloads of debris.

So, I have this concept with K-Briq, says Medero, which is that we can take that waste from construction demolition, recycle it, and make a new material that could go back to a site, she says, and not end up as landfill or filler, but instead become an architectural material through the application of the really clever bit, says Chapman, which is a binder that we add to our aggregate, he says.

Image: Donald Milne.

The K-Briq is, then, waste aggregate bound up such that it coheres as a brick, and the blended material from which it is formed looks like moist sand, for want of a better description, says Chapman, but is what we’d call a semi-dry mix that doesn’t flow, he says, but you can form it into moulds, so we just put it into presses under hydraulic pressure and then leave it to cure for 24 hours, he says, after which time it’s ready to go.

So it’s a simple thing, a beautiful thing, says Chapman, with a lot of complexity and innovation inside, but mimicking a very basic thing, and no cement, no fire, insofar as curing is a hardening process in which it’s the brick’s internal chemistry that does the bonding, he says, not high-energy fossil fuels.

Curing a brick is not a new idea, given that calcium silicate bricks are made by compressing a mixture of damp sand and lime and then curing the result with saturated steam in an autoclave, says Campbell, which was a process that was invented in Germany in the 1880s, he says, although those bricks are still extractive of raw materials, whereas the K-Briq is made from more unpredictable waste streams.

And so if you set out to design a waste brick, knowing how to cook is helpful, says Medero, because I never follow recipes – I have done dishes so many times that I now adapt to the ingredients, she says, and in the process of developing the K-Briq I realised that I similarly needed to understand material range, she says, the range within materials that was acceptable to ensure that the formula for the brick can cope with a composition that shifts between batches, she says, because waste is always going to have variation.

Kenoteq does not source its waste directly from demolition sites and doesn’t sort it in-house, but instead works with certified waste handlers who wash and screen it, says Chapman, which provides a degree of specification for the composition, but you’re still getting recycled aggregate from different suppliers, which has come from different origins, different buildings, he says, so you might have more brick in there than stone, you might have more concrete than brick, he says, which is the very nature of recycled materials because they’re not a nice homogenous thing.

This material complexity and tendency towards variation is one reason why the K-Briq has spent more than 10 years in development and why people think I’m going to be offended when they say that it just looks like a regular fired brick, says Medero, but the magic is that while there’s a lot of science and technology hidden in there, she says, it’s just a brick.

There are forebears to the K-Briq in the form of historical bricks also produced using waste, such as the yellow London stock bricks that provided the predominant building material of Georgian London, and which were formed from clay mixed with what has been variously known as Spanish, soil, town ash, or rough stuff, says Alan Cox in ‘A Vital Component: Stock Bricks in Georgian London’, that is, London’s domestic rubbish, which contained a large amount of ash and cinders, he says.

Which really latched onto my brain, says Bosence, whose practice has come to specialise in the local production of architectural materials, because I couldn’t think of another major city in the world that was made of its own waste, he says, and this idea also resonated with Groarke, who recently worked with Bosence and his partner, landscape architect Loretta Bosence, on developing an unfired brick of their own, with the idea that this could provide an interesting cultural conversation about technology, says Groarke, and the idea of balancing this notion of tradition and invention in architecture.

Like the K-Briq, Groake and Bosence’s brick is made from compressed construction waste, which is a little bit of a self-reflective process on how easy our choices as architects are, says Groarke, and about balancing this limitless freedom that we have as people putting the ingredients of buildings together, he says, because we should really be evaluating the modes of production that we make our buildings from.

But how many of us as architects truly research the origins of the materials that we’re specifying? he says.

Image: Donald Milne.

Hence the Gent Waste Brick, developed as part of Carmody Groarke’s ongoing project to renovate Design Museum Gent, Belgium’s national design museum, which includes a heavy emphasis on adaptive reuse of the museum’s existing buildings, Groarke says, as well as a new extension.

In developing ideas for the museum’s extension, and understanding its relationship to the existing museum buildings that date back to 1577, if not earlier, there was always the implication that this was going to be a brick building, says Groarke, and this curiosity about brick architecture was further piqued by local collaborator TRANS Architectuur, who kept repeating a phrase that everyone in Gent is born with a brick in their belly, he says.

From early on in the development of the museum’s masterplan, the idea of Gentian architecture in brick seemed normal, says Groarke, while the suggestion of reusing existing construction materials alongside adapting existing buildings gained resonance, given that the enduring, representational buildings in Gent are made from a soft, white limestone, he says, like the tower of St. Bavo’s Cathedral, which has been built and unbuilt and rebuilt and unbuilt and rebuilt several times between the 13th and 16th centuries.

So this current notion of circularity and creative adaptive reuse in architecture isn’t an innovative idea of the 21st century, says Groarke, but was present in the pre-modern era where freedom and limitless ways of production and use of materials were not possible, he says, and so we’re just reapplying that, because the way we construct should meet the challenges of the modern world, he says, and what better location to communicate that than in a design museum?

We can, Groarke says, rethink every technology around how we build.

The new Gent Waste Brick is made from 63 per cent municipal waste, extracted from waste streams drawn from across the city of Gent that we’ve been really judicious in our use of, says Sian Ricketts, an architect with Carmody Groarke, because something like concrete has pozzolanic qualities, she says, which is what you get in volcanic stone and things like that, meaning that it’s got inherent binding properties that we can benefit from.

To complete the bricks, this mixture of construction waste is combined with sand, hydraulic lime and ground calcium carbonate on a brownfield site in Gent, resulting in a brick with one-third of the embodied carbon of a clay-fired brick, which is a great platform for saying that here’s an example of how we can cut 65 per cent or so of the carbon out of this unit of construction, says Groarke, which becomes a signpost for us to think a bit more critically about how we build.

Although only around 91,000 Gent Waste Bricks are being produced because I don’t think we’re interested in becoming brick manufacturers, says Ricketts, there is a heightened symbolic value to the project insofar as bricks are a symbol of architecture and something you can hold in your hand, she says, because bricks are used everywhere and are understood as a completely mutable scale of construction in almost every country in the world, adds Groarke, such that seeking to redesign the production process by which bricks are manufactured becomes a kind of existential question about construction.

Like the K-Briq, the Gent Waste Brick is cured rather than fired to lower its carbon costs, which is enabled by the fact that it uses lime as its primary binder, says Ricketts, and which results in a curing and drying process that, in total, takes around six to eight months, which is roughly similar to the timescale a clay brick would go through with firing and cooling, says Bosence, but the whole premise was that we didn’t want to have an initial expenditure of carbon, he says, so the design was all based around the fact that it would not go into a kiln.

And when a kiln is taken out of the equation, the need for transportation of materials is also reduced, because the beauty of all this is that it opens up fabrication, says Bosence – you’re just pressing these bricks on-site and letting them cure, rather than moving them elsewhere to a kiln, he says, and so we have also tried to design all of this around existing moulds and existing pressing machines that don’t need to be adapted, he says, because all this infrastructure exists and is already quite common.

Image: Donald Milne.

In order for the brick to cohere correctly, however, the makeup of its various waste aggregates needs to be carefully considered, says Groarke, which means that the Gent Waste Brick is mostly concrete buildings that have been pulverised, he says, but it also contains elements of porcelain, and elements of glass.

The latter originally came from Belgian beer bottles, says Groarke, but the residue of sugars from the alcohol was still there even after washing again and again, and we washed it five times, says Ricketts, but there’s a combination of the glucose of the beer and the residue from the label which was incompatible with the chemical process of curing, she says, so we had to select different streams of glass, she says.

And car windscreens have been very good instead, says Groarke.

But while this selection of aggregates is chiefly functional, it has also been calibrated to generate a particular aesthetic, such that the Gent Waste Brick is a white-grey or dove-grey brick that is designed to match the city’s historic limestone or, as Bosence says, just a boring brick, just a pale brick, he says, not a wonderfully beautiful object, not a wonderfully refined object, he says, so people will not get wowed with the glitziness of it, but will instead focus on the narrative, which is to show people where materials are from.

To show people that you can make stuff from what’s around you, he says.

This approach towards local production intends to provide an alternative idea for the procurement of building materials moving forward, because we automatically think of mining as being of a raw material, says Ricketts, but there’s a lot of value in mining waste streams given that we’re going to meet a tipping point, she says, where waste is more than the raw material available out of the earth.

Because a brick is made of surrounds and we are all surrounded by waste, and our cities are actually very rich for material movement, says Bosence, which is happening everywhere, he says, but it’s so hard to keep hold of that material because there’s often no storage, no place to fabricate.

So to be able to make 91,000 bricks within the city of Gent, for the city of Gent is as strong a narrative as the materiality of it, he says.

The Gent Waste Brick is telling a hyperlocal story about making a building through the physical substance of the city, says Groake, but you can also write this brick as a design code that you can apply to a different part of the world with its own waste streams, says Bosence, where you will get a brick that looks different, he says, inasmuch as it would be the same size and shape, the same function, he says, but look completely different.

This relationship between specificity and universality pivots around standards and legislation, insofar as the Gent Waste Brick has been cleared for use on Design Museum Gent, but only after lots of conversations with the Belgian Union for Technical Approval in Construction, says Ricketts, which were about being able to demonstrate that the brick was suitable for use and met various performance metrics, she says, but the brick has no wider authorisation for use in Belgium, let alone overseas, because the challenge is navigating standards and there is no standard for this brick, she says.

This is a problem for any waste brick, inasmuch as existing standards were developed for concrete bricks or for fired clay bricks, but our brick is not fired, says Ricketts, so it’s more of a living material in a way, which means it’s softer, perhaps a little softer, she says, and these slight differences in performance require careful adaptation of the way in which you design using the material.

So it has been quite key, she says, that alongside developing the brick we have also been developing the detail of the building, and had the space and time to think about the interrelation of the two, she says, like the decision to incorporate an overhanging parapet on the museum’s facade that can help to protect the brick.

While these issues around usage have been challenging for the Gent Waste Brick, they represent a higher hurdle for the K-Briq, which is a commercial product intended for more straightforward specification in projects, which means that we needed to look at all the most extreme tests from all the standards of things that could be considered even close to us, says Medero, who has adopted a particular focus on the damage that can occur within bricks due to weather conditions, so I have been freezing and thawing bricks for more than a decade, she says.

For which living in Scotland has actually helped, she says, because if you make bricks that you have successfully exposed to the elements for five winters in Scotland, she says, then you feel OK about their future performance, even if the K-Briq is still subject to the British standards, the European norms, says Chapman, and those standards have come about over many years of development around traditional materials and products, he says, which fit very nicely for a concrete block or a clay-fired brick, but where there’s nothing to fit a brick made out of waste material that isn’t fired, he says.

Image: Donald Milne.

Development routes for architectural materials vary dramatically from country to country, and some are more accommodating than others, so if you go to Germany there is a route, says Medero, and New Zealand has some nice standards too, but here in the UK there’s nothing, she says, which really stifles new things entering the market, says Chapman, because even for the K-Briq to not simply be classified as waste takes regulatory steps with the environmental agencies, he says.

Today, the K-Briq is in the final stages of its certification with the British Board of Agrément, which is looks at the standards and gives you a testing specification, says Chapman, but there’s been a lot of to and fro with the environment agencies, he says, which ultimately amounts to an extended timespan that has been frustrating for a project aimed at addressing environmental issues within construction, because time is pressing, he says, and what we’re doing now affects things well into the timeframe of the climate emergency.

So there is a need for greater regulatory speed, which is a theme picked up at StoneCycling by Ward Massa, because while developing an idea or a new material as a sample can be challenging enough, says Massa, transforming that into something that can be sold in a conservative industry is the real challenge, he says.

StoneCycling produces fired WasteBasedBricks, which are made from mostly mineral waste streams, and those can be ceramics, can be glass, can be post-industrial waste streams, says Massa, but also other types of polluted earth sources such as materials dredged out of harbours, he says, so that in total we have about 60 different waste streams that can be used, but not all 60 actually are used, he says, because legislation is often not up to speed with development.

Which is one reason why the WasteBasedBrick is made from at least 60 per cent waste, mixed with raw clay, because while on a laboratory level we can go up to 100 per cent waste, says Massa, if we don’t add clay, then it’s not a clay ceramic product anymore, he says, and you find yourself in a field where there are no regulations or test methods, which is not simply a matter of complying with legislation, but also to do with gaining market traction, he says, because a construction company is responsible for the quality of the building, which means that they want to work with proven methods and materials.

And that’s really a force that goes against innovation, he says, because doing something new means potential risks. The WasteBasedBrick is the most established of the current generation of waste bricks, having initially been developed by Massa’s former partner, designer Tom van Soest, in 2009 as a graduate project at Design Academy Eindhoven, before finally launching in 2015 as a commercial product, during which time we have intentionally tried to become part of a system of already existing products, says Massa, because at least we have norms that we can use for testing and people understand what kind of material it is, he says.

Slowly, we can now start to increase our ambition because the market knows us, says Massa, but we always say that, for any step we can take in the laboratory, we should divide that by two for the market, he says, because a lot more is possible than what people will accept.

The corollary of this approach is that the WasteBasedBrick remains conventionally fired as opposed to cured, which has resulted in an in-between step of compensating the carbon footprint and changing the recipe to fire at a lower temperature, says Massa, while the next step is to switch to a hydrogen-fired production process that will give you the temperatures but no carbon emissions, he says, because in the end this needs to be 100 per cent waste-based, and it needs to be carbon neutral.

And alongside the environmental complications, a further result of the firing process is that the WasteBasedBrick is the most conventionally brick-like of the waste bricks, adopting the aesthetic of a clay-fired brick that is produced in a range of familiar, brickish tones, because aesthetics are super important, says Massa, and there’s a reason why everyone wants to live in a brick building, he says, whereas the K-Briq has leant into the provision of stronger, brighter colouration through the introduction of recycled pigments such as blue and chartreuse and pink and violet.

These colours are unorthodox, but aimed at helping the product cope with the vicissitudes of trends within the market, because we want to be flexible to our clients, says Medero, so if tomorrow they want yellow bricks, then the factory will produce yellow bricks, she says, and if orange is in fashion the day after, then we’ll do that.

Which is aesthetically unconventional, but not unheralded because most people think of bricks as being red, says Campbell, when in fact they have been produced in every colour under the sun, including the pale yellows of the desert, the bright green glazes of the Middle East, the purples and blacks of so-called Staffordshire Blues, he says.

Image: Donald Milne.

Colour within bricks is often a tell as to material origin, insofar as historically bricks were vernacular and you got different colours wherever you travelled in the world, says Bosence, on account of the different brickearths from which they were made, alongside natural variations in their production, he says.

So where Local Works Studio is based in East Sussex, he says, the bricks are orange and red from the iron in the clay that oxidises during firing, but you also get these flashes from the kiln that deposit this lovely blue-y glaze.

Whereas here in Scotland, Medero says, they like the blacks and greys.

But if brickearth is removed from the mixture, colour can be left far more open, because a link between production and locale has been severed, so while we do want to mimic the more traditional colours, says Chapman, we also offer the more wacky colours too, which is part of a wider ambition to position K-Briq as not only a manufacturer, but also a brand.

Launching a brand is a familiar commercial ambition, but also unusual given that there aren’t really any brands in the brick world, says Chapman, because while a brick is just a brick, branding is also a statement of Kenoteq’s environmental position and of wanting people to get on board with the idea that we’re about something bigger than making a few bricks, he says, because if a house is built with these things, it means waste has been avoided.

To facilitate these ambitions, Kenoteq is opening a factory on farmland east of Edinburgh, which will take in the region’s waste and use it to mass-produce the K-Briq as a commercial product, because while a brick produced in the lab is great, says Chapman, there’s nothing commercially viable until it is produced in the numbers required by the construction industry, but the requirements of material development mean that any startup working to reach this scale faces considerable costs.

So we’ve needed public-sector grant funding and research funding, says Chapman, and then some fundraising through more traditional private equity, he says, because while you may have a good idea, and you’ve maybe got it to small-scale prototype, you still need a couple of years to really develop all the stuff around the commercial side, and none of that happens without that kind of support, says Massa, because there’s an enormous amount of time between somebody liking your product and a company actually buying your product – years and years and years, he says.

Kenoteq has now reached the end of a pilot programme producing 400 bricks a day, but 400 a day is not viable commercially, says Chapman, so the next step is 10,000 a day, which amounts to producing 3m bricks per year, says Medero, but in a UK market of 2.6bn bricks per year that is a drop in the ocean, that is small fry, says Chapman, because Persimmon Homes put in a new concrete brick-making plant a couple of years ago that’s doing 80m bricks a year, he says, and some on the continent will be 150 or 200m.

StoneCycling, meanwhile, produces 2m bricks a year, achieved in partnership with a production company that specialises in developing bricks for the renovation industry, which means they have to be able to remake historic brick recipes, says Massa, so their factory is super flexible, although there are now plans to move to a new, dedicated facility that will allow production to upscale to 25m bricks a year.

Yet an upturn in production numbers need not mean catering to market demands, because we think that the architectural market will change in the coming years, says Massa, from the situation we have at the moment where an architect gets an assignment, starts designing, and then looks for companies that can make the materials they need, he says, to a situation where there is a location that needs a building, the architect looks at the available materials, and then makes a building out of those, he says.

This has implications for production companies who may no longer say that I have this brick that you can buy now and you can also buy the same one in 10 years, says Massa, but who may be more like I have 500,000 of these bricks, who can do something with them? he says, while a similar idea has led Kenoteq to speculate about setting up a franchise or licensing model for its bricks, because we need to follow the materials, says Chapman, follow the resources.

So if you want a load of bricks in New York State, he says, then why not make them there yourselves, which is the real future for all this because cities are our mines now that we’ve dug up everything, he says, so we need to be nimble and start replicating these sites elsewhere, he says, because if you’ve suddenly got five or six of them, all doing 10m bricks a year, that’s when we’ll start to see a real impact.

Image: Donald Milne.

And animating all these ideas is the demand for architecture to adopt a greater responsiveness towards material availability, which is the overarching theme informing the practice of Local Works Studio, because as architects it’s really, really good to stop and reconsider everything, says Bosence, because we can’t carry on as we are.

So Local Works does not operate as a conventional studio, but has instead been desperately trying to get into projects early, says Bosence, earlier than architects being brought in to design a building for a site, but rather beginning during any prior demolition process in order to ring-fence materials before they’re labelled as waste or taken off site, he says, which has resulted in the use of an architectural process called a pre-deconstruction audit in which you go to a site and rather than just getting on with demolition, recycling, blah, blah, blah, he says, you do an audit of all the materials you have, which then becomes your palette for repurposing and reuse.

Because part of our role can be to open up architecture to show people how things are made, says Bosence, to show people the craft of it, to show people where materials are from, and that you can access materials locally and form buildings and landscapes from them, he says.

All of which stands in contrast to the status quo of architecture and development, Groake says, because this is a point less about the bricks themselves, he says, and more about focusing on and valuing the origins of ingredients, to which Bosence’s palette of on-site repurpose and reuse sets an admirably high bar, but which needn’t be impossible to achieve given that even something as simple as greater organisation of off-site waste storage centres would represent a considerable step along the way.

Belgian waste streams, for instance, are very beautifully organised, says Ricketts, with all the various materials separated, which makes them relatively easy to work with, she says, whereas I get the impression from looking into access to waste in the UK, she says, that there’s more red tape, so if we’re going to start utilising the resources available to us, she says, we really need to get better at organising them.

If any of this is to be successful, it will likely require legislation to ensure that the construction and demolition industries account for these matters, because the will from many architects is already present, says Chapman, and the waste handlers themselves get this because they see a value in everything, he says, so it’s just about getting the broader processes right.

Yet until this happens, more ecologically responsible materials will come with attached costs, because WasteBasedBricks are at the high end of bricks, says Massa, and we know that 90 per cent of the market is not our market, he says, which is the same situation as experienced at Kenoteq, who are not trying to compete on price yet, says Chapman, because we know that big house builders will go direct to companies who are cheaper.

Ultimately we are collecting materials that need to be sorted, says Massa, and there’s a lot of processes involved in that which drive up the cost, but if you look at the actual cost of a brick, he says, you should also take into account its environmental impact and the cost to the environment through its ongoing use.

To which there are construction solutions, because alternative material options are out there, says Chapman, but it’s about getting them known and getting the mentality right for specifiers and more traditional builders, he says, which is where architects can help, because a brick is a very normative unit of construction, says Groarke, and if we can inflect the thinking behind how we make these units, he says, then that’s very appealing.

Much of this is not new, because contemporary approaches often reconfigure scraps of past practice, which you can see encapsulated in the 1955 lecture ‘Art and Technology’, delivered at the Academy of Finland by the 20th-century Finnish architect Alvar Aalto, in which he explains how an ordinary brick is for all appearances a primitive product, but if it is made correctly, he says, properly processed from the country’s own raw materials, if it used in the right way and given its proper place in the whole, then it constitutes the basic element in mankind’s most valuable and visible monuments, he says, and is also the basic element in the environment that creates social wellbeing.

So in working with waste in 21st-century construction, there is potential for social and environmental wellbeing to be reemphasised, because at another point in his life, Aalto recalls having been in Milwaukee together with my old friend Frank Lloyd Wright, who gave a lecture that began with: Ladies and gentlemen, do you know what a brick is?

And in response to his own question: a brick, Wright says, is a small, worthless, ordinary thing that costs 11 cents but has a wonderful quality.

Give me a brick, Wright says, and it becomes worth its weight in gold.

Which was the first time I had heard an audience told so bluntly and expressively what architecture is, Aalto says, because architecture is the turning of a worthless stone into a nugget of gold.

Words Oli Stratford

Photographs Donald Milne

This article was originally published in Disegno #35. To buy the issue, or subscribe to the journal, please visit the online shop.